Hornby R253 Dock Shunter repair (clean and service)

One very common problem with older Hornby locomotive models is that of poor running especially at slow speeds. The loco keeps stopping and pausing. The loco becomes almost unusable and tends to be put to one side. This is especially true as very often there isn't a clear fault with the loco, everything is present and seems OK.

This is how we get engines in this condition running smoothly again.

This great little Dock Authority loco is complete but runs very poorly, especially at slow speeds. It keeps stopping. At higher speeds it seems to run better.

Below are a series of pictures showing how with a simple clean and service this R253 Dock Authority model Locomotive has been given a new lease of life.

With the cover removed, at first glance everything looks present and correct. Everything is just how it should be and there are no obvious causes for the poor slow speed operation.

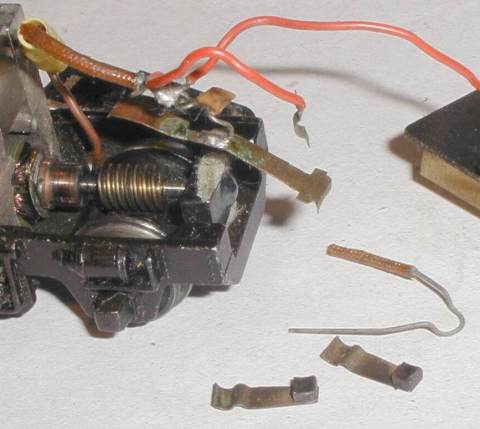

A more detailed inspection revealed the problem. This level of corrosion and dirt is very common in locos of this age. Especially those that have not been serviced regularly. The corrosion might not look much but being present in so many of the electrical connections it has a large cumulative effect.

In this picture the green coloured corrosion can be more clearly seen on the X.67 motor brushes, brush spring and the brush contact strip.

There is also a build up of carbon dust between the segments of the motor commutator.

At this stage all the electrical contact faces have been polished to bright shiny metal. This includes; wheels, axles, contact strip, brush spring, brushes, brush contact, wheel pick-ups. The picture shows the polished wheels and brushes clearly.

The armature has been checked for any concerns and any other problems are put right.

The motor magnet is magnetised in situ in the motor.

The chassis has been cleaned as has the body of the loco.

The chassis has been reassembled, lubricated and thoroughly tested at both high speeds, low speeds and in both directions.

Finally the cover is refitted and the loco tested again. Perhaps this little R253 Dock Authority shunter doesn't look too different from the outside but it's track performance is much improved with the clean and service complete.

Ready for another period of solid reliable service on the Hornby model railway.