Hornby R084 Class 29 diesel BO BO service including the Ringfield motor

This Hornby R084 Class 29 BO BO diesel electric locomotive was running rough and the owner had tried to clean the Ringfield motor commutator, but this didn't fix the problem. The Hornby locomotive was sent to us for a full service.

This is what we found and how we got this wonderful locomotive running very smoothly again.

This great Hornby model of a Class 29 diesel electric locomotive is complete but runs poorly on the track. Everything else seems OK so a full service of the locomotive was undertaken.This Hornby locomotive was manufactured in around 1979, so a good service is long overdue.

Below are a series of pictures showing how, with much methodical work, this Hornby R084 Class 29 diesel electric locomotive was brought back to life.

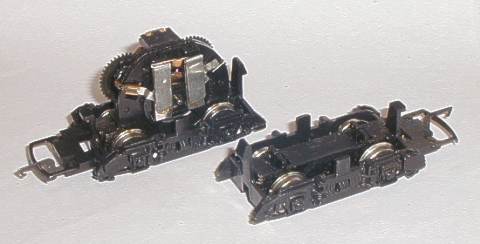

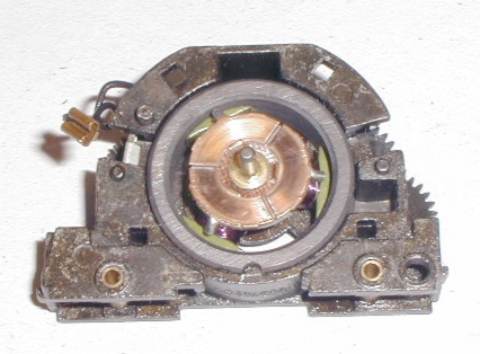

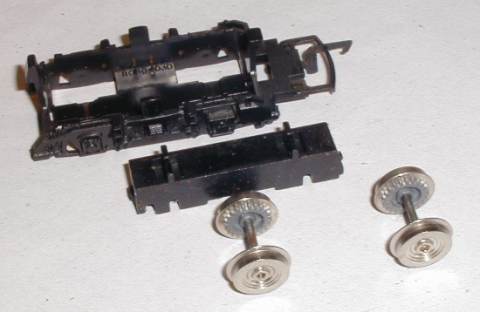

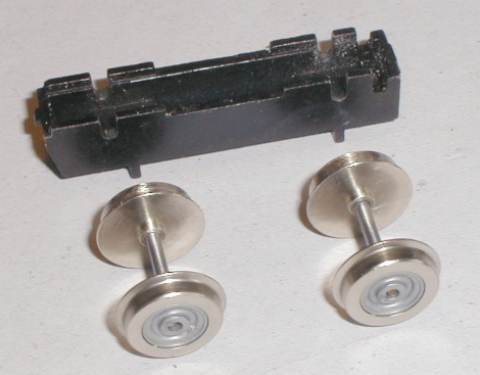

The first task is to remove both the bogies and the connecting wire from the Hornby locomotive body. This image shows both of the bogies with nothing looking too wrong at the moment. The drive bogie is fitted with the very common Hornby Ringfield motor which was fitted to many Hornby locomotives of the period.

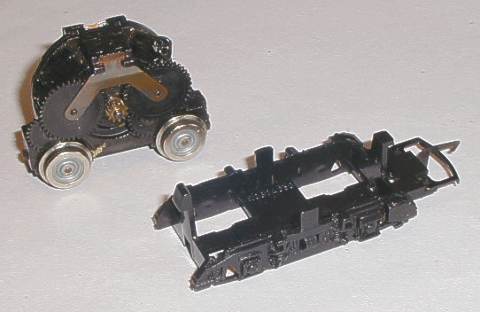

We serviced the drive bogie first and the first step of this is to remove the drive unit from the plastic bogie housing.

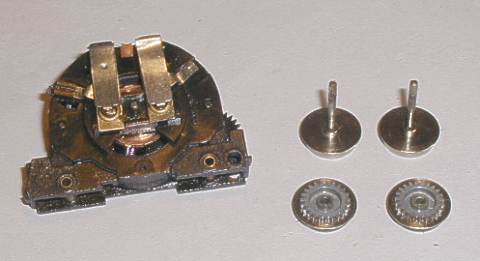

The next task is to remove the drive axles and wheels from the drive unit.

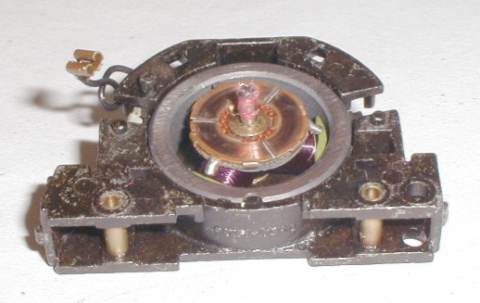

Next the motor brushes and springs are removed. Gently lift the spring clamps to reveal the brush springs. The springs are fully trained escape artists so handle with great care. They can ping much further than you could think possible.

We slide them into a shaft of a very fine screwdriver to control them.

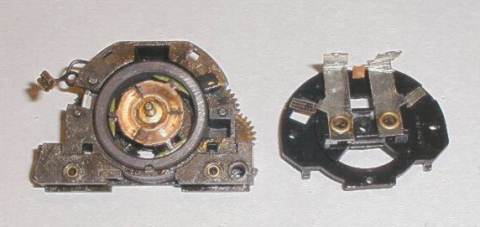

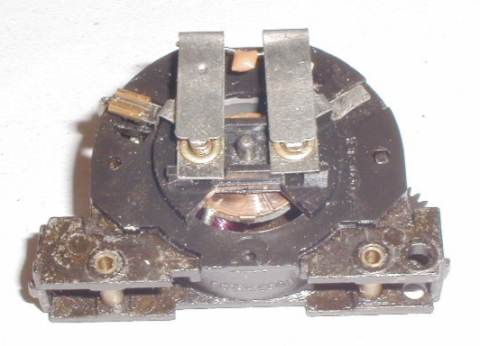

Then the Hornby Ringfield motor end plate is removed to reveal the motor commutator. This commutator was a little dirty but with no damage. The motor windings were inspected and tested too.

The insides of the drive axle tubes are cleaned with the use of a very colourful pipe cleaner. This removes all the old grease and oil from inside the tubes.

Next we cleaned and polished the commutator including the spaces between the commutator segments. Any carbon from the Ringfield motor brushes can build up in these spaces. In turn this can cause a short circuit between the commutator segments leading to burning of the commutator insulator and the end to the motor.

With the commutator cleaned and polished we then cleaned the Hornby Ringfield motor end plate. Again the colourful pipe cleaner does the job. Remove all grease, oil and carbon dust that may be present.

Add a small smear of Teflon grease to the Ringfield motor shaft. Not too much as it could get onto the commutator, and that's not good. DO NOT use oil on this bearing, grease only.

Refit the Hornby Ringfield motor end plate. It simply clicks into position. Make sure it's fully seated. Refit the wire to the chassis tag.

Then, clean and refit the motor brushes and springs. The springs will do everything they can to escape so be patient and make sure the springs are correctly engaged in the ends of the spring clamps.

Damaged or badly worn motor brushes must be replaced.

Clean and polish the drive axle shafts and the running surface of the pick-up wheels.

Check for wear and damage to the traction tyres and replace if you are not sure about their condition. These tyres were scrubbed to regain the necessary traction.

Refit the drive axles and drive wheels to the motor assembly. DO NOT add oil or grease. The materials used by Hornby are self lubricating at the speeds encountered in this application.

Testing the drive unit, both directions at high and low speeds.

The smooth running Hornby Ringfield drive unit is clipped back into the plastic bogie housing.

Next, we turned our attention to the non-drive bogie. This bogie is the electrical pick-up for the other track rail. So it too must be cleaned.

The axle shafts and pick-up wheels were cleaned and polished as were the contact points in the metal housing.

The non-drive bogie is re-assembled making sure the wheels are fitted the right way round. Essentially, the drive bogie picks up from one track rail and the non-drive bogie picks up from the other track rail.

DO NOT add oil or grease. The materials used by Hornby are self lubricating at the speeds encountered in this application.

Locos of this period and motor type can suffer a problem at the crimp connection at the motor end of the connecting wire. As can be seen from the image the wire insulation is not removed and an electrical connection is made (or not) by the tips of the crimp piercing the insulation.

We have seen too many of these crimps fail to leave this alone. So we cut the wire off and make a traditional solder joint.

Maybe not so pretty, but definitely more reliable.

Re-assemble the bogies back into the body of the Hornby locomotive and make the electric connections.

Here's the completed loco on a test track. We test for high speed and slow speed performance in both directions.